FH Series Wire-Cut EDM

4-Axis Linkage | Environmental Design | Intelligent Database

Key Specifications

Wire Diameter

0.16 ~ 0.20 mm

Machine Weight

≈1200-1500 kg

Precision (3 times cutting)

0.005mm

Best Surface Finishing

Ra 0.8μm

Water Tank Capacity

≈150 L

Filter Type

Single pump circulation

Operating System

RUJUN 1.0

Interface Language

Chinese / English

Storage for Files

64G(120G) SSD

Power Consumption

2KVA

4-Axis Linkage

- Advanced 4-axis (X,Y,U,V) hybrid control system

- Enables complex contour machining and taper cutting

- Precision control for intricate shapes and profiles

- Simultaneous movement for superior surface finish

- Ideal for complex molds and precision components

Environmental Design

- Eco-friendly design with reduced energy consumption

- Efficient filtration system minimizes waste

- Closed-loop water circulation system

- Low emission operation meets environmental standards

- Sustainable manufacturing solution

Intelligent Database

- Smart database with optimized cutting parameters

- Automatically adjusts settings based on material type

- Reduces setup time and improves cutting efficiency

- Self-learning capability improves with usage

- Stores thousands of material and cutting profiles

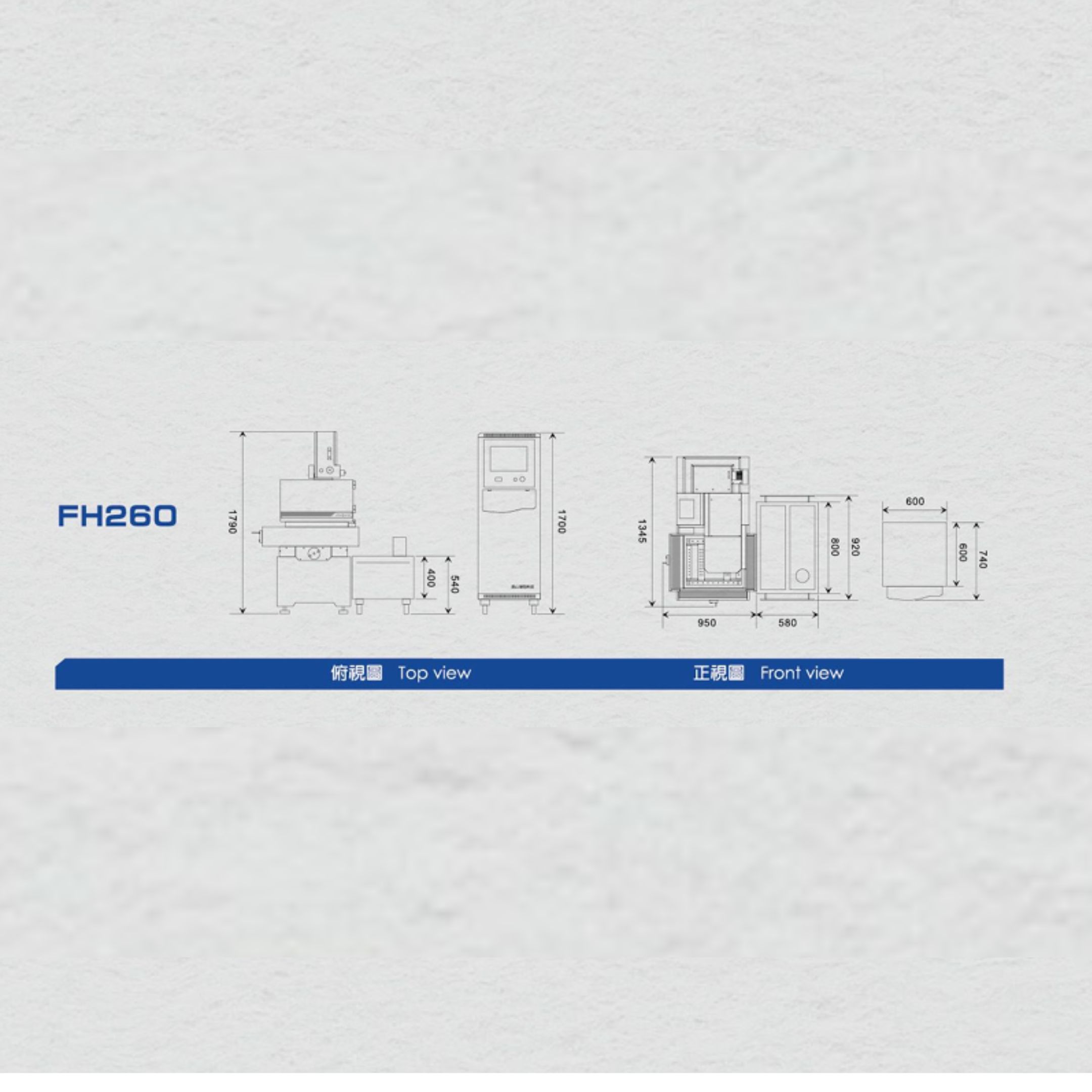

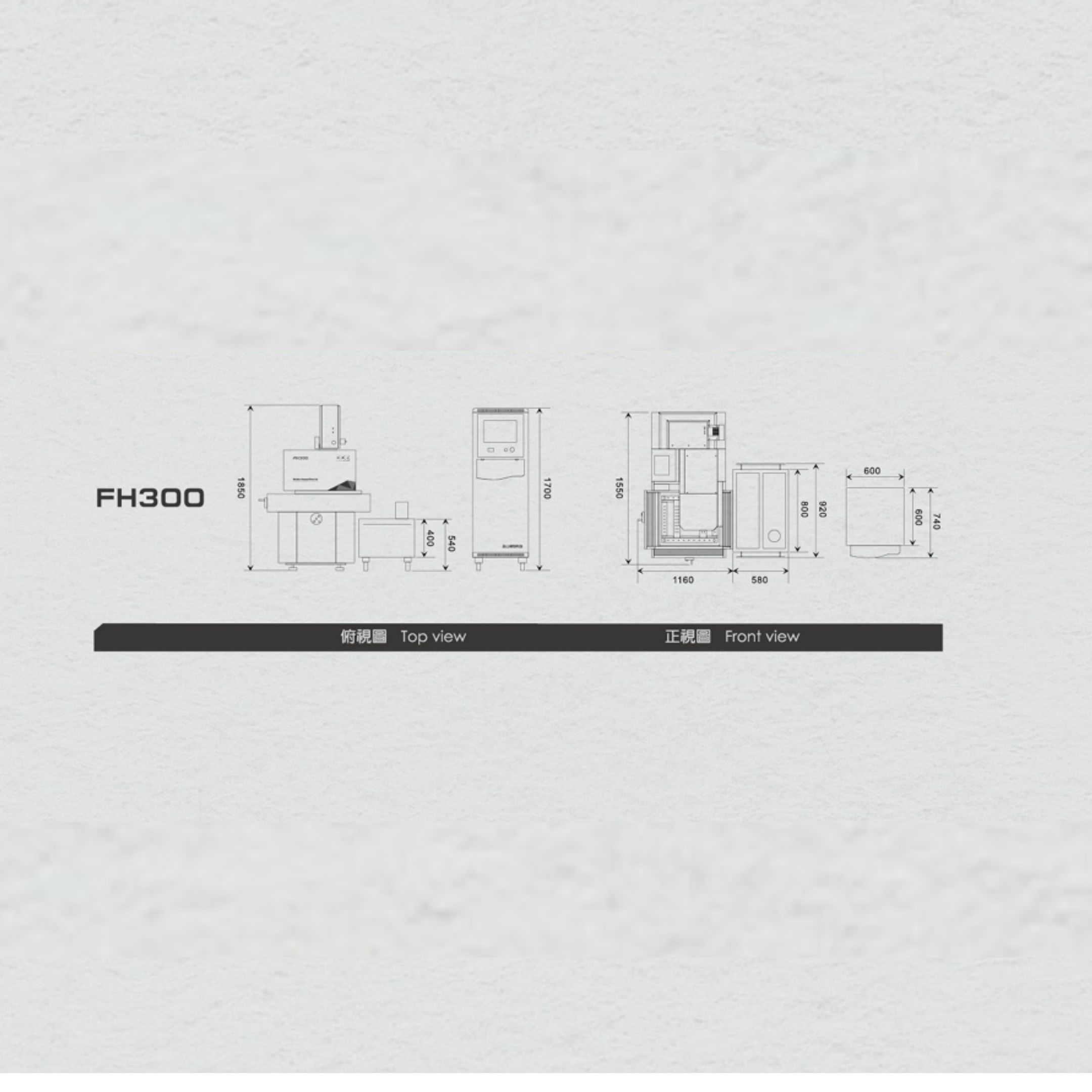

Model Specifications

| Specification | FH200 | FH200C | FH400C |

|---|---|---|---|

| Table travel (X×Y×Z) (mm) | 240×300×200 | 300×400×250 | 300×400×250 |

| Machine weight (kg) | ≈1200 | ≈1500 | ≈1500 |

| Working tank size (W×L) (mm) | 450×600 | 550×680 | 550×680 |

| Max work-piece weight (kg) | 350 | 350 | 350 |

| Water tank size (W×L×H) (mm) | 580×860×530 | 580×860×530 | 580×860×530 |

| Water tank capacity (L) | ≈150 | ≈150 | ≈150 |

Technical Specifications

Max Cutting Taper/Angle

±6° (80mm high)/±10° (80mm high)

Working Tank Size

450×600 mm to 550×680 mm

Max Work-piece Weight

350 kg

Precision (3 times cutting)

0.005mm (12mm×12mm×30mm hexagon)

Best Surface Finishing

Ra 0.8μm

Drawing Format

G code, DWG, DAT, DXF

Connect Type

USB unit, LAN cable

NC Linkage Axis

4 axis (X,Y,U,V) Hybrid

Min Command Unit

50mm/min

Input Power Capacity

220V 50~60Hz

Ambient Temperature

10°~35°

Applications

Precision Tooling

Manufacturing of precision molds, dies, and tooling components

Automotive Parts

Production of intricate automotive components and transmission parts

Electronics Industry

Fabrication of delicate electronic components and connector parts

Medical Devices

Manufacturing of surgical instruments and medical implant components